Avanteclad Modular Solutions Pvt. Ltd. manufactures modular cleanroom partitions, ceiling systems, and allied components tailored to industry-specific requirements.

With a manufacturing capacity of 500,000 sq. m. modular partitions annually and 21,000 cleanroom doors per year, we deliver solutions aligned with the stringent standards of pharmaceuticals, medical devices, semiconductors, solar PV, microelectronics, and FMCG sectors.

Controlled environments in pharma demand cleanability, airtight segregation, and long-term compliance with cGMP and WHO guidelines, enabled by modular walls, cleanroom ceilings, cleanroom doors, special construction doors, view panels, and precision cleanroom accessories designed for seamless integration and contamination control.

Factory made pre-defined cut-outs

View Products : Walls | Ceiling | Cleanroom Doors |Special Construction

Fabrication facilities operate under Class 1 to Class 100K environments, where low outgassing and ESD-safe surfaces are non-negotiable.

Avanteclad systems provide:

Applications: Wafer fabs, chip packaging facilities, assembly plants, and microelectronics R&D labs.

Category 1

Category 1

View Products : Walls | Ceiling | Cleanroom Doors |Special Construction

High-throughput solar panel manufacturing requires thermal stability, corrosion resistance, and modular scalability.

Avanteclad solutions include:

Applications: PV cell assembly lines, lamination areas, and dust-sensitive module packaging zones.

View Products : Walls | Ceiling | Cleanroom Doors |Special Construction

Sterility, bio-safety, and validation compliance define medical device manufacturing spaces.

Avanteclad solutions enable:

Applications: Implant manufacturing, diagnostic kit production, and sterile device packaging.

Hygiene, cleanability, and corrosion resistance are critical in food-grade environments.

Avanteclad systems feature:

Applications: Food processing units, dairy plants, beverage bottling lines, and FMCG packaging.

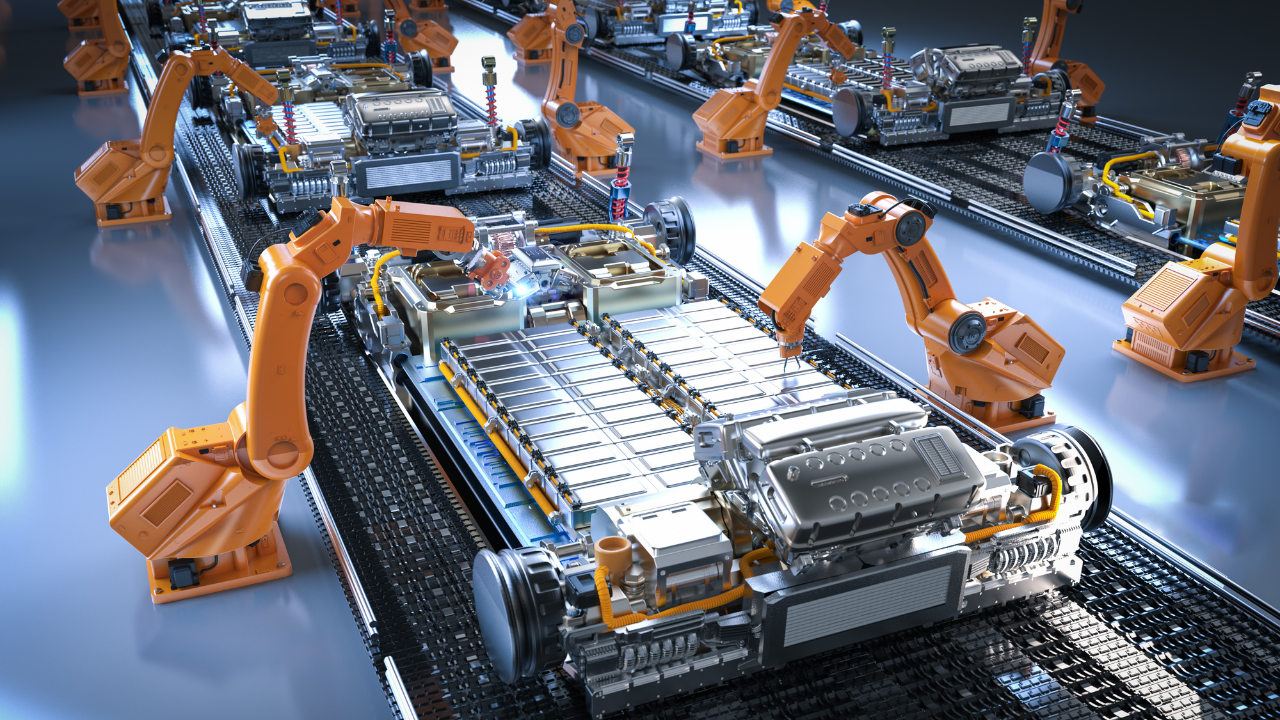

Emerging sectors like EV and battery production demand controlled dust environments and fire-rated enclosures.

Avanteclad offers:

Applications: EV battery assembly, paint shops, component clean zones, and advanced R&D facilities.

View Products : Walls | Ceiling | Cleanroom Doors |Special Construction

35,000 sq. ft. Vadodara unit with 1.5 lakh sq. ft. world-class infrastructure for scalable production.

Equipped with advanced systems from European, Canadian, and American OEMs for precision output.

Smart automation reduces manual intervention, ensuring faster throughput and consistent product quality.

Close to Mundra and Nhava Sheva ports, giving projects an assured edge in timely global deliveries.

Backed by 25+ years of cleanroom expertise through ACES.

Annual capacity of 500,000 sq. m. partitions and 21,000 cleanroom doors.

Configurable panels, ceiling grids, and door systems tailored to operational needs.

Built for ISO, GMP, FDA, and EN13501 fire standards.

Progressive systems cut installation time by 30–40%.

Avanteclad continues to align its modular cleanroom solutions with evolving industrial standards, ensuring scalability, compliance, and operational stability across global markets.

Avanteclad Modular Solutions LLP

Plot no. 89, Survey/Block No. 1028, Hari Om Industrial Park, Paldi Kankaj, Tal : Daskroi, Dist: Ahmedabad-382425

BF77, Opp. Hari Nagar Bus Depot, Janakpuri, New Delhi-110058

Email: contact@avanteclad.in

Ph: 011-45508664, 45650702, 45650714

Avanteclad Modular Solutions LLP

Manufacturing Facility- Plot no. 89, Survey/Block No. 1028, Hari Om Industrial Park, Paldi Kankaj, Tal : Daskroi, Dist: Ahmedabad-382425

Head Office- BF77, Opp. Hari Nagar Bus Depot, Janakpuri, New Delhi-110058

Email: contact@avanteclad.in

Tel: 011-45508664, 45650702, 45650714

Avanteclad Modular Solutions LLP

Manufacturing Facility- Plot no. 89, Survey/Block No. 1028, Hari Om Industrial Park, Paldi Kankaj, Tal : Daskroi, Dist: Ahmedabad-382425

Head Office- BF77, Opp. Hari Nagar Bus Depot, Janakpuri, New Delhi-110058

Email: contact@avanteclad.in

Tel: 011-45508664, 45650702, 45650714